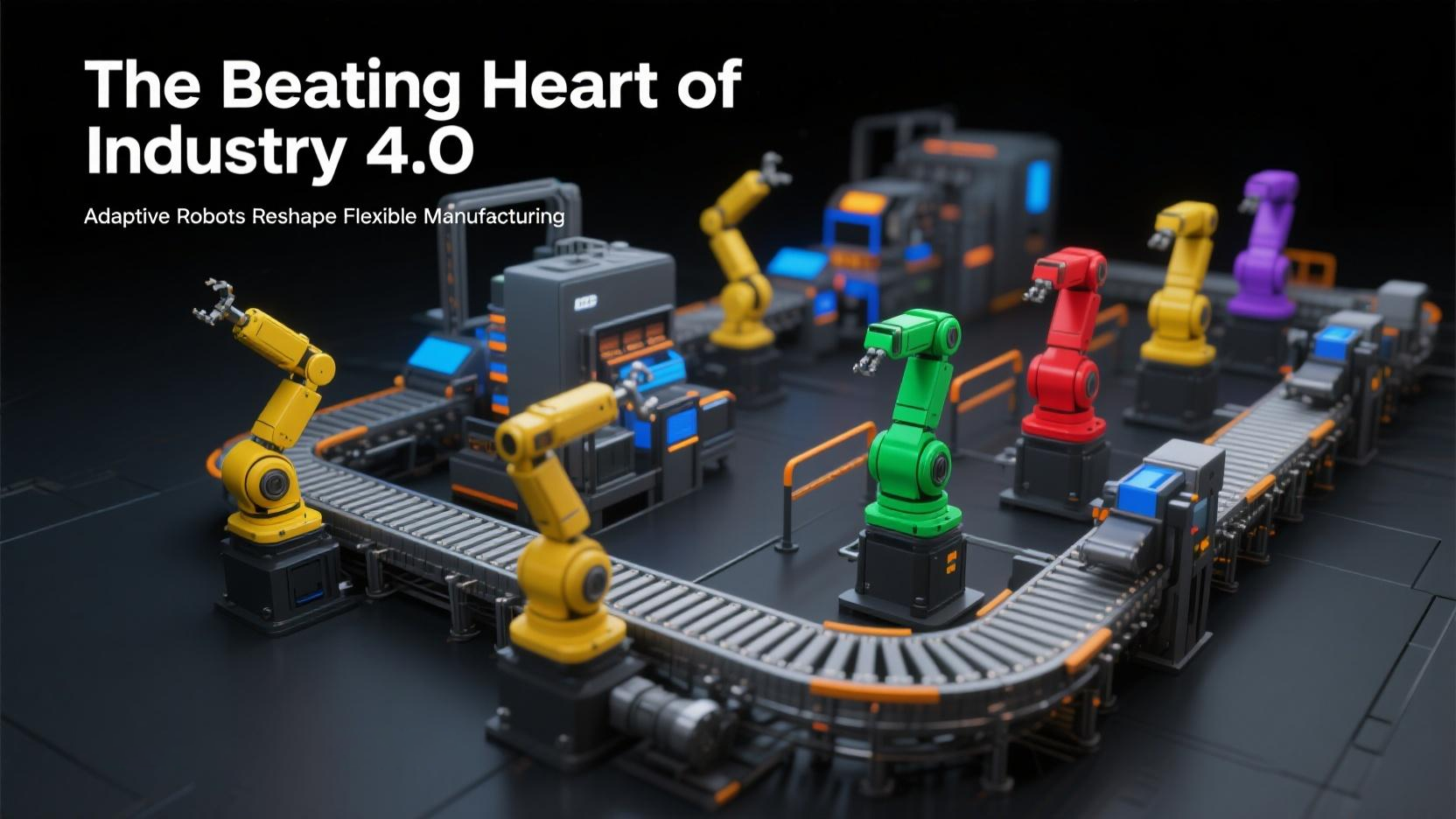

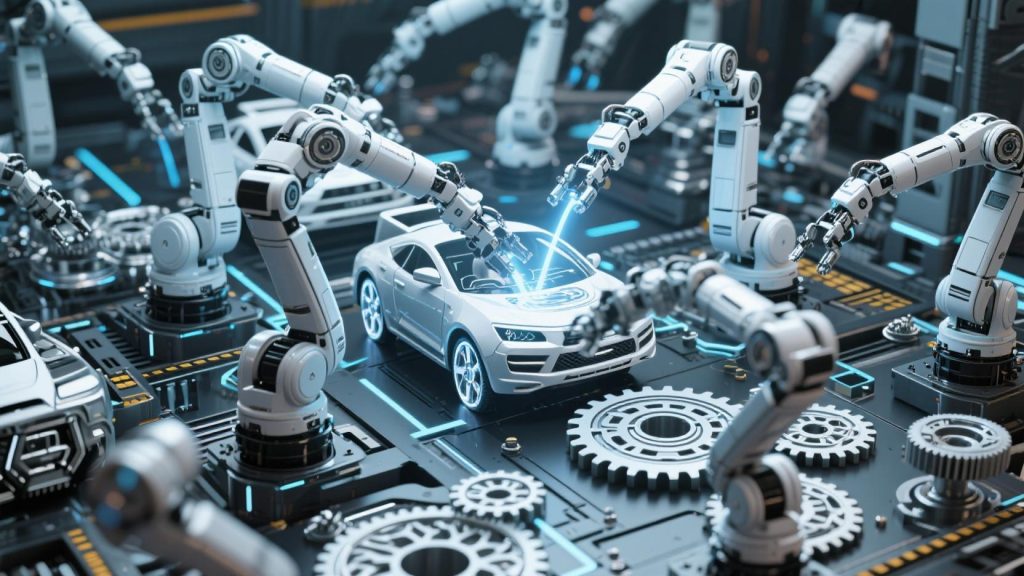

In the age of Industry 4.0, the line between intelligence and automation is dissolving. Nowhere is this transformation more evident than in Siemens’ Amberg factory, where a “cognitive production line” is redefining the future of mass manufacturing. Here, robotic arms are equipped with multimodal sensors and integrated with digital twin systems, enabling them to compare over 100,000 production models in real-time. Within 0.1 seconds, these machines autonomously switch modes, adapting their operations to exacting demands without human intervention.

The BMW Leipzig plant has taken this paradigm further in 2025. The factory introduced zero-programming adaptation: when a new car model is introduced, robotic systems automatically generate welding paths using visual localization, reducing production line reconfiguration time from six weeks to just 72 hours. This leap represents not just an upgrade in efficiency, but a radical shift in production philosophy.

Historically, manufacturers faced a core trade-off: scale versus customization. Larger volumes meant lower costs, but at the expense of flexibility. Now, adaptive robotics is rewriting that equation. The new frontier is the tension between agility and complexity. As systems become smarter and more interconnected, manufacturers can respond faster to market changes—but only if they can manage the rising intricacy of their operations.

China’s “Lighthouse Factories” illustrate this shift vividly. These cutting-edge facilities, recognized by the World Economic Forum, show that adaptive production lines can reverse the traditional economy of scale. In some cases, small-batch, high-variability orders have proven 12% more profitable than large-scale production runs. The machines not only produce—they learn, evolve, and optimize in a continuous feedback loop.

This level of agility transforms not only production but entire business models. Manufacturing is no longer a linear pipeline; it’s a dynamic ecosystem. As software-defined machines integrate with cloud AI and edge computing, factories are becoming living systems, capable of near-instantaneous responses to shifts in demand, design, or supply chains.

Yet, with this power comes new complexity. Adaptive systems require robust cybersecurity, real-time data orchestration, and a new breed of hybrid workforce that blends robotics expertise with domain knowledge. As robots make decisions once reserved for engineers, the role of human oversight becomes more strategic than operational.

The industrial revolution now unfolding is not merely about automation—it’s about cognition. Machines are no longer tools; they are collaborators. The beating heart of Industry 4.0 is not just faster production—it’s smarter, more humane manufacturing, where adaptability is not a feature, but a foundation.

In this world, the winners won’t be those with the largest factories, but those with the most intelligent, adaptable systems. The future of manufacturing is not about size—it’s about response time, resilience, and the reinvention of process as possibility.