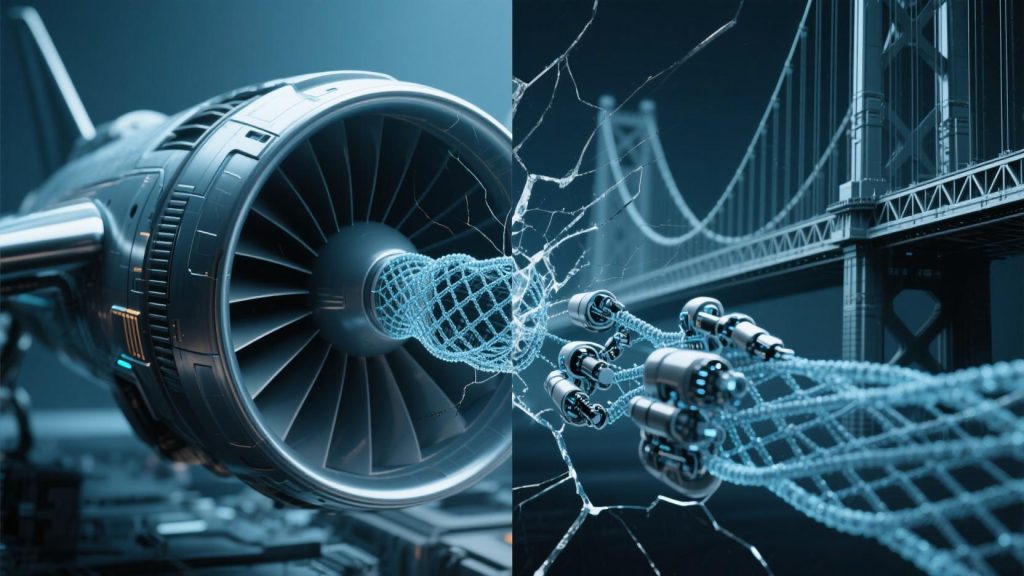

In 2025, Boeing and Airbus began deploying autonomous self-healing alloys across next-gen aircraft. These materials feature microfluidic veins that circulate liquid metal. When a stress crack appears on a wing, embedded carbon nanotube robots activate, initiating shape-memory repair protocols. Full microstructural healing completes within 72 hours, mid-flight certified.

On the ground, China’s Hong Kong–Zhuhai–Macao Bridge uses self-propagating concrete, where embedded bacteria mineralize calcium carbonate within fractures—restoring integrity up to 110% of the original strength.

Industrial Shockwaves: Repair Is No Longer a Business Model

The impact is seismic:

The global MRO (Maintenance, Repair, and Overhaul) market is projected to shrink 60% by 2030. Manufacturing shifts from “build–replace” to “subscribe–regenerate”. Rolls-Royce now trials engines that self-heal and charge clients per flight hour, turning breakdown into a billable feature.

A Paradigm Flip: Matter as Active Agent

The revolution lies not in materials that passively endure damage, but in ones that actively correct it, fusing robotics, nanotech, and bio-mineralization. These materials encode intent, turning infrastructure into autonomous caretakers of their own integrity.